Overview

Welding is a very common process in metal processing. You may know that welding is the process of connecting two metal materials together. But few people can clearly understand the principles of welding and the differences between various welding methods.

In this article, we will introduce the principles of welding, common terms in welding, and different welding methods in detail. I believe that by reading this article, you will have a systematic understanding of the welding process.

What is Welding?

Welding is a process that uses high temperature or high pressure to fuse multiple metal materials together. At high temperatures, metals melt into liquid and become fluid. At this time, the metal liquids that are bonded together will mix. After cooling, the liquid metal solidifies, and the two metal materials are tightly bonded together. The figure below shows the principle of welding.

There are many ways to heat metals, such as arc, laser, ultrasound, friction, etc. Among them, arc is the most common way to heat metal, and the welding process using this heating method is called arc welding. Most of the welding methods introduced in this article belong to arc welding. If you don’t know what arc is, we will introduce it in the next chapter.

By heating the bonding surfaces of two metals, they can be directly welded together. However, since it is difficult to ensure good bonding between metal surfaces, direct welding is relatively inefficient. Therefore, most of the time, welding materials are needed as a medium to fill the gap between the two metal surfaces, which is why welding materials are also called filler metals.

Common Welding Terms

Arc

Arc is a gas discharge phenomenon. It is also considered a plasma. Normal gas is non-conductive, but the gas between two electrodes will be ionized, and the gas atoms will be decomposed into gas ions and free electrons. At this time, the gas is conductive and will produce sparks, which is an arc. Arc discharge generates a lot of heat. Arc welding uses this heat to weld. The picture below is a typical arc.

Shielding Gas

In the article introducing heat treatment, we mentioned that metal heated in air will be oxidized to form a black oxide scale. The oxide scale is an impurity that affects the performance of the metal. If you don't want the oxide scale to be produced, you need to isolate the air during heating. Shielding gas plays such a role in welding. The common shielding gas is argon. During welding, the welding gun releases shielding gas while it is powered on. The shielding gas also acts as a conductor for the arc.

Molten Pool

Welding only heats a small part of the metal, so most of the metal is still solid, and only the small part that is heated is liquid. These liquids are in the form of pools on the metal surface, which are called molten pools. After solidification, the molten pool forms a part where the metals are fused.

Slag

In some specific welding methods, there are chemical compounds involved in the welding process. Such as coating, core, flux, etc. These substances will also melt during welding, and these melted substances are called slag. In the article introducing smelting, we have mentioned that slag can absorb impurities in the metal, thereby improving the chemical composition of the metal. Since the density of slag is often lower than that of metal, it will float above the molten pool to form a slag pool. Therefore, slag also has the function of isolating air. After solidification, solid slag will adhere to the surface of the weld and can be easily removed.

Common Welding Materials

As mentioned above, two metals can be directly welded together by heating. However, in order to improve the welding effect, it is more common to use welding materials. Below we introduce three commonly used welding materials.

Filler Metal

Filler metal is the most commonly used welding material. Its shape is very similar to that of ordinary wire. However, it should be noted that the chemical composition of filler metal may be slightly different from the corresponding grade. According to the product form, filler metal can be divided into welding wire and welding rod. Welding wire is continuous and coiled on the spool. Welding rod is long strip. Filler metal can be used in many welding methods. In actual welding, the shape and size of filler metal need to be selected according to different welding methods and specific conditions.

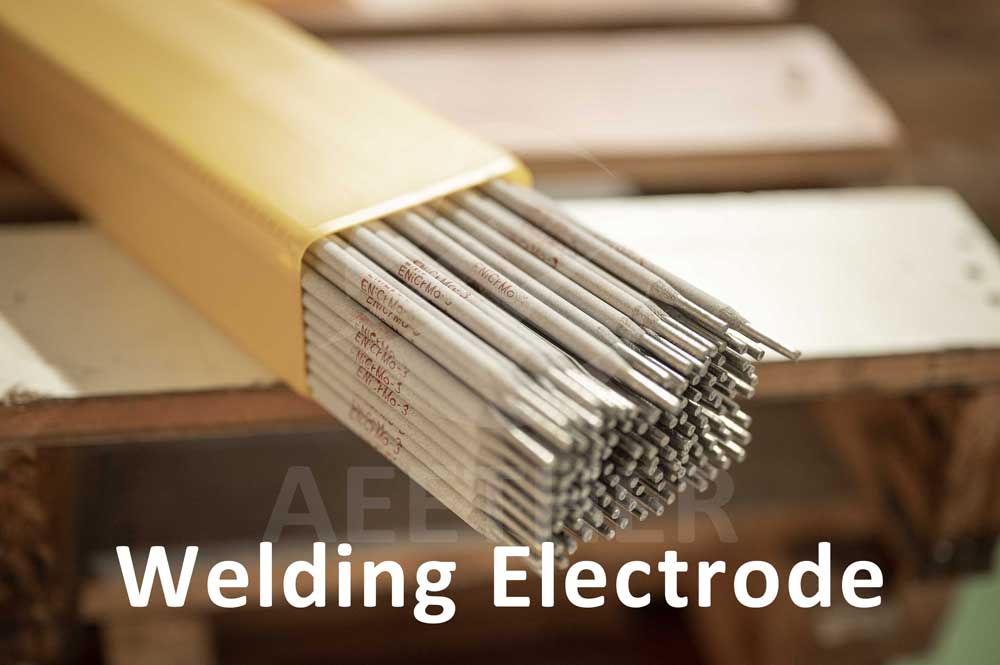

Welding Electrode

Welding electrode is suitable for SMAW welding. In addition to the metal core, the surface of the welding electrode is also covered with a layer of coating. The coating forms slag after welding to improve the chemical composition and performance of the weld. The welding electrode is long strip and also available in different sizes. Welding electrode can be welded without shielding gas.

Flux-cored Welding Wire

Flux-cored welding wire is the opposite of welding electrode. It has filler metal on the outside. In the center of the metal is the flux core, which also turns into slag after melting. Unlike welding electrode, flux-cored wire is often wound on a spool. Flux-cored wire can also be welded without the use of shielding gas.

Common Welding Methods

SMAW

SMAW is shielded metal arc welding. It requires welding electrode as welding materials. During welding, the welding material is used as one electrode and the metal weldment is used as the other electrode. SMAW does not require shielding gas. The coating itself will release a certain amount of gas, and after the coating melts, a slag pool will be formed to further protect the molten pool.

SMAW has the advantages of simple equipment and flexible operation. It can be welded in various positions and can weld different materials. However, since SMAW requires manual operation, its production efficiency is low and the labor intensity is high.

GTAW

GTAW is also called gas tungsten arc welding. It has the same meaning as TIG (tungsten inert gas). This welding method does not use welding materials as electrodes, but tungsten as electrodes. Argon is used as shielding gas when GTAW welding, so it can directly weld metal or use welding rods to weld. Manual wire feeding is required when welding with welding rods, so it requires welders to have certain experience.

GTAW has a large current density and high welding temperature, so its welding efficiency is high and it can weld various different metals. At the same time, since there is no coating, GTAW welding will not produce spatter, and the weld is more beautiful. In addition, this welding method is easy to automate, which further improves efficiency.

However, GTAW equipment is relatively complex and has a high learning cost. In addition, due to the high welding temperature, there is a phenomenon of local annealing near the weld, which is a problem that needs attention for some high-strength materials.

GMAW

GMAW and MIG (metal inert gas) are the same welding method. Its full name is gas metal arc welding. The welding equipment of GMAW is very similar to GTAW, and argon is also used as the shielding gas. The difference is that GMAW directly uses the welding material as the electrode instead of tungsten. Therefore, GMAW is automatic wire feeding, which also determines that it needs to use continuous welding wire.

GMAW also has a higher current density. At the same time, due to continuous wire feeding, GMAW has better welding continuity, which also improves welding efficiency. However, GMAW equipment is relatively complex, so the welding cost is higher for some cheap materials.

PAW

The full name of PAW is plasma arc welding. It is similar to the welding method of GTAW. They both use tungsten as the electrode. The difference is that PAW compresses the arc by directly spraying plasma gas. The energy density of this arc is very high, and a deep molten pool can be formed. Therefore, PAW is very suitable for welding thicker metal materials. However, due to the high speed of compressed gas injection in PAW, the air flow will be turbulent, and there will be a risk of air mixing during welding.

FCAW

FCAW stands for flux cored arc welding. It is almost the same welding method as GMAW. The only difference is that the welding material is changed to flux-cored wire. Since the flux core and shielding gas protect the molten pool at the same time, the materials welded by the FCAW method have very good purity and beauty. The welding efficiency of FCAW is also very high.

However, due to the complex manufacturing process of flux-cored wire, FCAW is relatively uncommon, and it is often used for welding with very high requirements.

SAW

SAW stands for submerged arc welding. The key to submerged arc welding is granular flux. These fluxes will bury the weld. Similar to the coating of the electrode, they not only play the role of isolating the air, but also can be used as slag to optimize the performance of the weld. Submerged arc welding is highly automated, so welding wire is also needed as a welding material.

SAW has stable welding quality, high welding efficiency, no arc light, no dust and smoke. It is almost harmless to the human body. However, SAW welding is relatively simple and is not suitable for complex workpieces. At the same time, SAW is difficult to weld thicker materials.

ESW

ESW stands for electroslag welding. It can solve the problem that SAW cannot weld thicker metals. Before welding, the weld needs to be kept vertical, and then the flux is heated at the weld to form a slag pool. As shown in the figure below:

During welding, the slag pool needs to be continuously energized to maintain a high temperature. Then, the welding wire is placed in the slag pool. The melted welding wire sinks to the bottom of the slag pool to form a molten pool. At this time, the copper cooling sliders on both sides of the weld will solidify the molten pool at the bottom. The continuously fed welding wire will continue to push up the molten pool and slag pool. Finally, the entire welding is completed.

ESW is suitable for welding thicker metals. However, the welding temperature of ESW is high, which is easy to change the internal structure of the metal. Therefore, after ESW welding, the metal often needs to be heat treated by normalizing and tempering.

Brazing

Brazing is a special welding method. The melting point of the brazing welding material is lower than that of the metal weldment. Therefore, during brazing, the welding material will melt while the weldment remains solid. The melted welding material will enter the gaps of the weldment and bond them together.

Brazing is a simple process with low temperature, so it will not affect the performance of the metal. However, the strength of the weld seam is low and it is not suitable for welding high-strength metals. Brazing is often suitable for welding parts with high precision.

Flat Welding, Butt Welding and Socket Welding

According to the different welding connection methods, welding can be divided into flat welding, butt welding and socket welding. These welding methods are generally suitable for pipe fittings and flanges.

Flat welding refers to welding directly on the metal surface. For example, when welding a flange to a pipe, the pipe needs to be inserted into the flange port first, and then welded at the contact surface between the pipe and the flange. Flat welding is a simpler welding method and does not require beveling. However, the sealing of flat welding is relatively poor.

Butt welding refers to aligning the ports of two pipes and welding at the joint of the ports. The following figure is a schematic diagram of butt welding. Butt welding requires beveling at the pipe end, so the sealing is better.

Socket welding is similar to flat welding. The difference is that there is a groove inside the socket welding flange, which fixes the insertion depth of the pipe and supports the port of the pipe. At this time, welding is performed on the contact surface between the flange and the pipe. The sealing of socket welding is also not as good as butt welding, and it is often used on smaller pipes.

FAQ

Are the metal at the weld and the metal weldment the same in terms of performance?

Although welding can connect metals together, the microstructure of this connection is far less stable than the weldment metal itself. This is why the pressure bearing capacity of seamless pipes is stronger than that of welded pipes.

Why are the components of some welding materials different from those of the weldment itself?

The composition of welding wire is specially designed. Some components in welding materials are strictly controlled to improve the performance of welding.

Can different grades of metal be welded together?

Yes, some welding materials can weld multiple kind of metals. For the specific welding range, please refer to the AWS standard.

Further Reading

Conclusion

Welding is the process of joining metals by partial melting. Electric arc is the most common heating method. At the same time, in order to avoid metal oxidation, it is necessary to isolate the air during welding. Welding performance can also be improved by welding materials during welding. This article introduces 8 welding methods. Different welding methods should be used according to different welding requirements.

We supply welding materials for various nickel alloys. Please contact us if you have any needs.