Inconel Alloy X-750 (UNS N07750)Coil Tube

- AEETHER

- Inconel Alloy X-750 Pipes

- Coil Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Aging Treatment

100% Tested by

Hydrostatic Pressure

Excellent High

Temperature Strength

Inconel X-750 Coil Tube Supplier

As a leading Inconel tube supplier, AEETHER manufactures and produces high quality and customized Inconel X-750 coil tube.

INCONEL® alloy X-750 (UNS N07750 / W.Nr. 2.4669) is a precipitation-hardenable nickel-chromium alloy used for its corrosion and oxidation resistance and high strength at temperatures to 1300°F. Although much of the effect of precipitation hardening is lost with increasing temperature over 1300°F, heat-treated material has useful strength up to 1800°F.

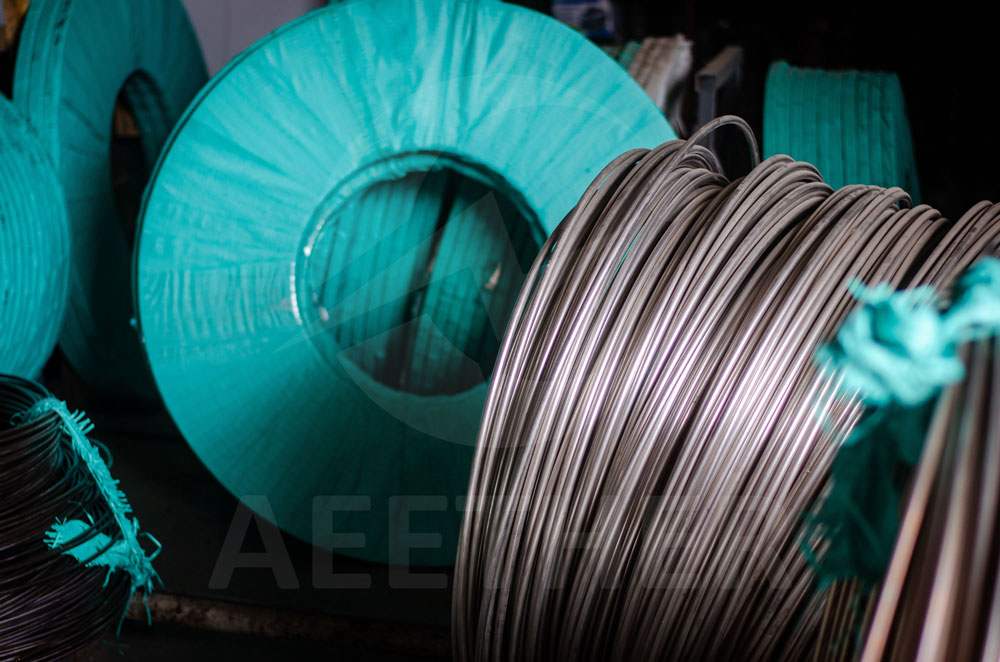

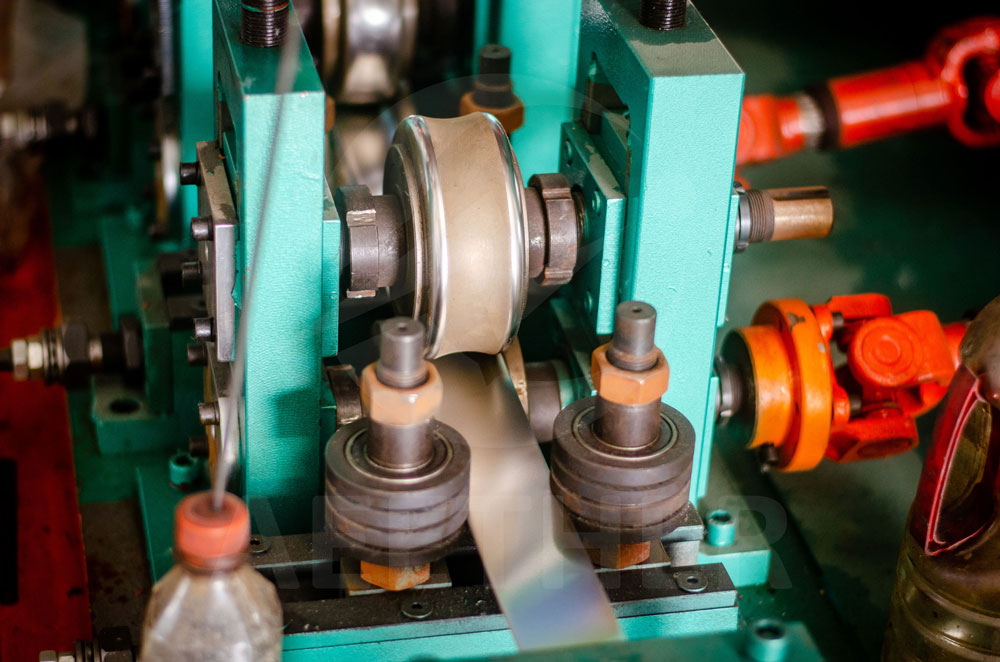

Inconel X-750 coil tube is a continuous small diameter Inconel X-750 tube manufactured by welding, continuously cold drawing and coiling the Inconel X-750 strip. Due to its continuity, we will use bright annealing process to avoid the generation of oxide skin inside the tube. Inconel X-750 coil tubes have excellent high temperature resistance and corrosion resistance, as well as good integration. We also provide Inconel X-750 seamless coil tube and Inconel X-750 welded coil tube for your choice. It should be noted that due to the difference in technology, the length of the Inconel X-750 seamless coil tube of the same size will be less than that of the Inconel X-750 welded coil tube. Please confirm this with us.

Chemical Composition of Inconel X-750

*Chemical Composition According to SAE AMS 5582|ASTM B829|ASME SB 829

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Inconel X-750 Coil Tube

*We will strictly produce Inconel X-750 Coil Tube according to the standard

Data Sheet

Physical Properties

| Density | g/cm3 | 8.28 | |

|---|---|---|---|

| lb/in.3 | 0.299 | ||

| Melting Range | °F | 2540 - 2600 | |

| °C | 1393 - 1427 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Solution Treated | 965 | 552 | 35 | ... | ... |

| Aging Treated | 1069 | 689 | 20 | ... | ... |

*Mechanical Properties According to SAE AMS 5582|ASTM B829|ASME SB 829

Inconel X-750 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air