Inconel Alloy 718 (UNS N07718 / W.Nr. 2.4668)Seamless Pipe & Tube

- AEETHER

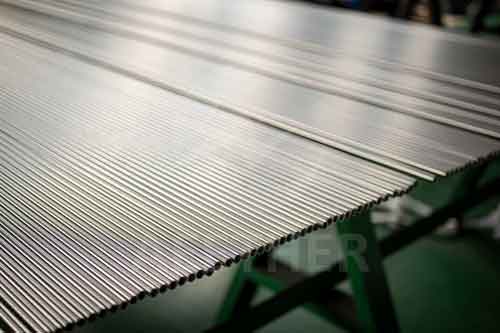

- Inconel Alloy 718 Pipes

- Seamless Pipe & Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Aging Treatment

100% Tested by

Hydrostatic Pressure

Excellent High

Temperature Strength

Inconel 718 Seamless Pipe & Tube Supplier

As a professional superalloy supplier, we manufacture high performance Inconel 718 (UNS N07718) seamless pipe & tube.

Inconel 718 is a precipitation-strengthened superalloy. It has very high strength at medium and high temperature. Therefore, this alloy is often used in parts that need to be stressed at high temperatures. Inconel 718 has many applications in the aerospace field.

We manufacture Inconel 718 seamless pipe & tube according to ASTM B983. We have complete cold rolling, cold drawing, annealing, pickling and other process equipment. Any size and performance needs are guaranteed. We will carry out solution treatment and aging treatment on the material according to the standard requirements, which will ensure the best high temperature strength of the material.

Chemical Composition of Inconel 718

*Chemical Composition According to ASTM B983

A certain amount of aluminum and titanium is added to the Inconel alloy. These two elements are important precipitation strengthening elements. They guarantee the high temperature strength of the alloy.

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Inconel 718 Seamless Pipe & Tube

*We will strictly produce Inconel 718 Seamless Pipe & Tube according to the standard

Try our Premium Products

Surface to be Customized

*We can also sandblast the pipes according to your requirements

Data Sheet

Physical Properties

| Density | g/cm3 | 8.19 | |

|---|---|---|---|

| lb/in.3 | 0.296 | ||

| Melting Range | °F | 2300 - 2437 | |

| °C | 1260 - 1336 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Aging Treated | 1034 | 862 | 20 | ... | 40C Max |

*Mechanical Properties According to ASTM B983

Suppliers shall heat treat alloys as follows:

Solution Treatment: 1875 ± 25°F (1024 ± 14°C) for 1 to 2 h, water quench;

Aging Treatment: 1425 - 1475°F (774 - 802°C) hold 6 to 8 h, air cool.

Inconel 718 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air