Inconel Alloy 690 (UNS N06690 / W.Nr. 2.4642)Seamless Pipe & Tube

- AEETHER

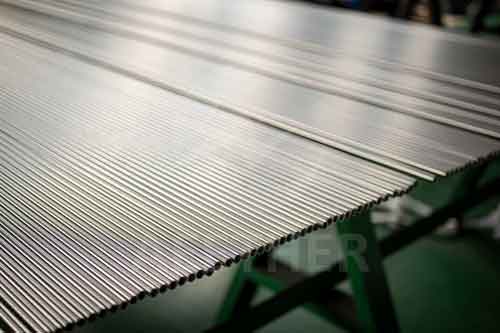

- Inconel Alloy 690 Pipes

- Seamless Pipe & Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

100% Tested by

Hydrostatic Pressure

Excellent High-temp

Oxidation Resistance

Inconel 690 Seamless Pipe & Tube Supplier

Inconel 690 is a nickel-based superalloy with excellent corrosion resistance and high temperature strength. It is ideal for use in extreme high temperature and highly corrosive environments. This alloy is mainly used in the manufacture of high-temperature equipment in fields such as petrochemical, aerospace and nuclear power plants. Among them, Inconel 690 seamless pipe & tube is a pipe product with very complicated production process. It provides excellent performance and reliability. ASTM B167 is the standard specification for Inconel 690 seamless pipe & tube. According to this standard, Inconel 690 seamless pipe & tube needs to meet strict requirements on chemical composition, mechanical properties and physical properties.

When producing Inconel 690 seamless pipe & tube, we use advanced cold rolling or cold drawing production process and strict quality control system. Only in this way can we ensure that the product has excellent performance and reliability. In addition, we can also customize according to customers' requirements, providing Inconel 690 seamless pipe & tube in different specifications and sizes.

Chemical Composition of Inconel 690

*Chemical Composition According to ASTM B167

The content of nickel, chromium, iron and other elements in the chemical composition of the alloy needs to be strictly controlled to ensure the corrosion resistance and high temperature strength of the alloy.

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Inconel 690 Seamless Pipe & Tube

*We will strictly produce Inconel 690 Seamless Pipe & Tube according to the standard

Try our Premium Products

Surface to be Customized

*We can also sandblast the pipes according to your requirements

Data Sheet

Physical Properties

| Density | g/cm3 | 8.19 | |

|---|---|---|---|

| lb/in.3 | 0.296 | ||

| Melting Range | °F | 2450 - 2510 | |

| °C | 1343 - 1377 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Hot-worked or hot-worked annealed / 5 in. (127 mm) in outside diameter and under | 586 | 205 | 35 | ... | ... |

| Hot-worked or hot-worked annealed / Over 5 in. (127mm) in outside diameter | 515 | 170 | 35 | ... | ... |

| Cold-worked annealed / 5 in. (127 mm) in outside diameter and under | 586 | 240 | 30 | ... | ... |

| Cold-worked annealed / Over 5 in. (127mm) in outside diameter | 586 | 205 | 35 | ... | ... |

*Mechanical Properties According to ASTM B167

Inconel 690 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air