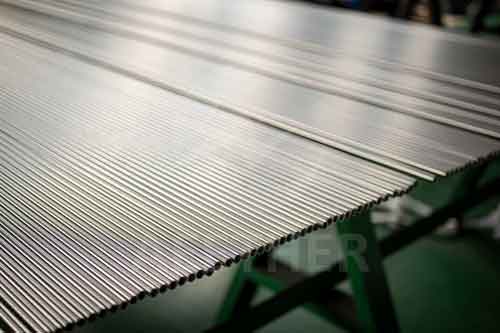

Inconel Alloy 686 (UNS N06686 / W.Nr. 2.4606)Seamless Pipe & Tube

- AEETHER

- Inconel Alloy 686 Pipes

- Seamless Pipe & Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

100% Tested by

Hydrostatic Pressure

Comprehensive

Corrosion Resistance

Inconel 686 Seamless Pipe & Tube Supplier

As a high-quality nickel alloy supplier, we produce cost-effective Inconel 686 seamless pipe & tube.

Inconel 686 is a nickel-based superalloy that has unparalleled corrosion resistance through the synergistic effect of high content of chromium, molybdenum and tungsten. Inconel 686 seamless pipe & tube can withstand strong acid, strong alkali and mixed media corrosion, far exceeding conventional stainless steel (such as 316L). In extreme corrosive environments and high temperature and high pressure conditions, Inconel 686 seamless pipe & tube have become an ideal choice for chemical, marine engineering, aerospace and other fields due to their unique chemical composition and excellent mechanical properties.

Choosing Inconel 686 seamless pipe & tube means choosing long-term safety and low maintenance costs! We provide customized specifications and professional technical support to help you meet the most demanding engineering challenges.

Chemical Composition of Inconel 686

*Chemical Composition According to ASTM B622

Nickel, as a matrix element, provides a stable austenite structure to ensure creep resistance and toughness at high temperatures. Chromium forms a dense oxide film to resist erosion by oxidizing media (such as nitric acid and hot concentrated sulfuric acid). Molybdenum and tungsten double reinforced pitting and crevice corrosion resistance, especially in chloride ion (such as seawater, hydrochloric acid) environment.

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Inconel 686 Seamless Pipe & Tube

*We will strictly produce Inconel 686 Seamless Pipe & Tube according to the standard

Try our Premium Products

Surface to be Customized

*We can also sandblast the pipes according to your requirements

Data Sheet

Physical Properties

| Density | g/cm3 | 8.73 | |

|---|---|---|---|

| lb/in.3 | 0.315 | ||

| Melting Range | °F | 2440 - 2516 | |

| °C | 1338 - 1380 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| All | 690 | 310 | 45 | ... | ... |

*Mechanical Properties According to ASTM B622

The strength of Inconel 686 is suitable for high-pressure pipeline systems. Excellent ductility avoids brittle fracture and adapts to complex processing and installation requirements. Inconel 686 still maintains strength below 600°C, and its oxidation resistance is significantly better than ordinary alloys.

Inconel 686 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air