Incoloy Alloy 800 (UNS N08800 / W.Nr. 1.4876)Seamless Pipe & Tube

- AEETHER

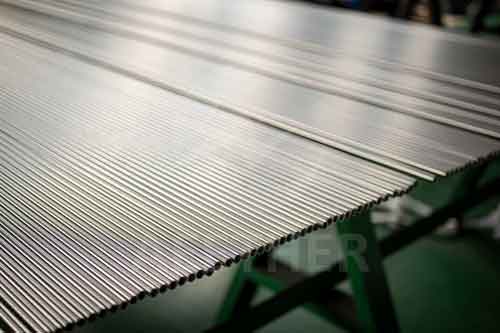

- Incoloy Alloy 800 Pipes

- Seamless Pipe & Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

100% Tested by

Hydrostatic Pressure

Good High-temp

Corrosion Resistance

Incoloy 800 Seamless Pipe & Tube Supplier

As a professional nickel alloy supplier, we manufacture Incoloy 800 (UNS N08800) seamless pipe & tube in various sizes.

Incoloy 800 is a commonly used superalloy. Its corrosion resistance and high temperature resistance are much better than ordinary stainless steel. At the same time, it has a lower price than the Inconel 600. Therefore, Incoloy 800 is a very cost-effective choice.

We manufacture Incoloy 800 seamless pipe & tube according to ASTM B163. We can offer two different delivery states, annealed and cold worked. We have pickled and polished surfaces to choose from. For each pipe, we will conduct hydrostatic testing and eddy current testing in strict accordance with the standard.

Chemical Composition of Incoloy 800

*Chemical Composition According to ASTM B407

Supplier shall perform chemical analysis of material in accordance with ASTM B880.

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Incoloy 800 Seamless Pipe & Tube

*We will strictly produce Incoloy 800 Seamless Pipe & Tube according to the standard

Try our Premium Products

Surface to be Customized

*We can also sandblast the pipes according to your requirements

Data Sheet

Physical Properties

| Density | g/cm3 | 7.94 | |

|---|---|---|---|

| lb/in.3 | 0.287 | ||

| Melting Range | °F | 2475 - 2525 | |

| °C | 1357 - 1385 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| Cold-worked annealed | 520 | 205 | 30 | ... | ... |

| Hot-finished annealed or hot-finished | 450 | 170 | 30 | ... | ... |

*Mechanical Properties According to ASTM B407

Cold-worked state is a state reached after the tube has been cold drawn or cold rolled. This state has high strength but low toughness. Annealed state is the state achieved by the material after heat treatment, which has relatively low strength but better fracture resistance. Suppliers should customize different delivery states according to standard requirements.

Incoloy 800 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air