Incoloy Alloy 330 (UNS N08330 / W.Nr. 1.4886)Capillary Tube

- AEETHER

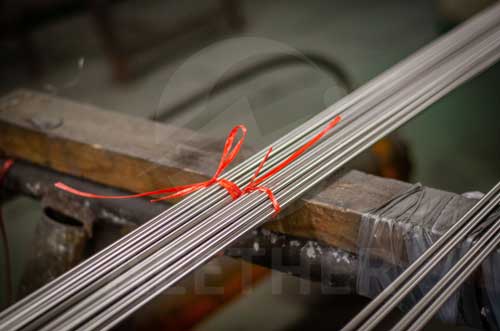

- Incoloy Alloy 330 Pipes

- Capillary Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

100% Tested by

Hydrostatic Pressure

Good High-temp

Corrosion Resistance

Incoloy 330 Capillary Tube Supplier

As a Chinese leading Incoloy supplier, AEETHER produces and manufactures precise Incoloy 330 capillary tube.

INCOLOY® alloy 330 (UNS N08330 / W.Nr. 1.4886) is an austenitic alloy with good high-temperature strength and corrosion resistance. It has a solid solution composition and is not hardenable by heat treatment. Its high nickel and chromium provide good resistance to oxidation and carburization. Its oxidation resistance is enhanced by the silicon content.

Incoloy 330 capillary tube is a kind of alloy tube with smaller size and higher process difficulty. It is made of Incoloy 330 coil tube straightened and polished. Incoloy 330 capillary tubes are suitable for use in some products that require high corrosion resistance and have a more precise internal structure. In terms of manufacturing process, we can provide seamless Incoloy 330 capillary tube and welded Incoloy 330 capillary tube. In the polishing process, we can provide MP, EP, BA, AP and other technologies to meet your different needs. The Incoloy 330 capillary tubes we produce have beautiful appearance, strict dimensional tolerances and suitable conditions.

Chemical Composition of Incoloy 330

*Chemical Composition According to ASTM B535 / ASTM B739

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Incoloy 330 Capillary Tube

*We will strictly produce Incoloy 330 Capillary Tube according to the standard

Try our Premium Products

Surface to be Customized

Data Sheet

Physical Properties

| Density | g/cm3 | 8.08 | |

|---|---|---|---|

| lb/in.3 | 0.292 | ||

| Melting Range | °F | 2520 - 2590 | |

| °C | 1380 - 1420 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell, max | |

| Seamless / Annealed | 483 | 207 | 30 | ... | 70-90B |

| Welded / Annealed | 483 | 207 | 30 | ... | 70-90B |

*Mechanical Properties According to ASTM B535 / ASTM B739

Incoloy 330 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air