Hastelloy Alloy C-22 (UNS N06022 / W.Nr. 2.4602)Seamless Pipe & Tube

- AEETHER

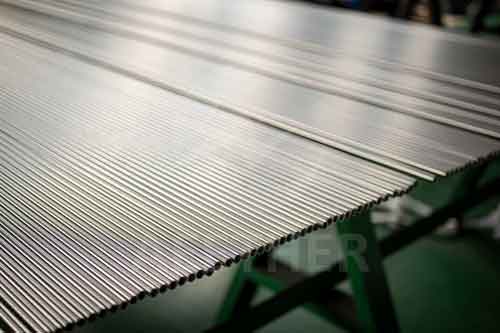

- Hastelloy Alloy C-22 Pipes

- Seamless Pipe & Tube

Quotation with

Valuable Data Sheet

Ship with MTC Acc.

to EN 10204/3.1

Quick Responce

within 24 Hours

Complete

Solution Treatment

100% Tested by

Hydrostatic Pressure

Excellent Comprehensive

Corrosion Resistance

Hastelloy C-22 Seamless Pipe & Tube Supplier

Hastelloy C-22 seamless pipe & tube is a high performance alloy pipe tube material. It has excellent corrosion resistance and oxidation resistance. Hastelloy C-22 seamless pipe & tube is widely used in chemical, aerospace, marine, energy and other fields. This product conforms to ASTM B622 standard and can guarantee the stability of product quality and specifications.

During the manufacturing process, we can use a variety of methods to ensure the quality and stability of the product. Such as eddy current flaw detection test, ultrasonic flaw detection test, dimensional detection and chemical composition analysis, etc. These inspections and tests can effectively guarantee the reliability and quality of the product, and ensure that Hastelloy C-22 seamless pipe & tube can meet the requirements of the standard.

In addition, we can also customize the size, length and surface treatment of Hastelloy C-22 seamless pipe & tube according to the specific requirements and needs of customers. Our products have high-precision dimensions and smooth surfaces, and can maintain stable performance in different environments.

Chemical Composition of Hastelloy C-22

*Chemical Composition According to ASTM B622

Hastelloy C-22 seamless pipe & tube is composed of high-purity metal elements such as nickel, chromium, molybdenum and tungsten. Among them, the content of molybdenum is as high as 12%. This gives the alloy excellent corrosion resistance.

Customized Dimensions

The size can be customized according to ASME B36.10 / ASME B36.19

*Customized size please confirm with us

Standards for Hastelloy C-22 Seamless Pipe & Tube

*We will strictly produce Hastelloy C-22 Seamless Pipe & Tube according to the standard

Try our Premium Products

Surface to be Customized

*We can also sandblast the pipes according to your requirements

Data Sheet

Physical Properties

| Density | g/cm3 | 8.69 | |

|---|---|---|---|

| lb/in.3 | 0.314 | ||

| Melting Range | °F | 2475 - 2550 | |

| °C | 1357 - 1399 | ||

Mechanical Properties

| Condition & Size | Tensile Strength | Yield Strength (0.2% Offset) | Elongation | Reduction of Area | Hardness |

|---|---|---|---|---|---|

| MPa, min | MPa, min | %, min | %, min | Rockwell | |

| All | 690 | 310 | 45 | ... | ... |

*Mechanical Properties According to ASTM B622

Hastelloy C-22 Applications

Other Informations

Package

Plastic Bag

Wooden Case

Logistics

By Sea

By Air