Overview

When importing nickel alloy products, we believe you will have a lot of worries.

Is there a problem with the composition of the material? Will the supplier substitute other cheap materials?

We very much understand this concern.

For end users, fake materials can affect the use time of the project, and cause security problems in the project.

For traders, this will seriously affect your credibility. Your clients will also no longer work with you.

In this article, we introduce 5 methods for controlling the quality of alloys. This can help you avoid 99% of material quality risks.

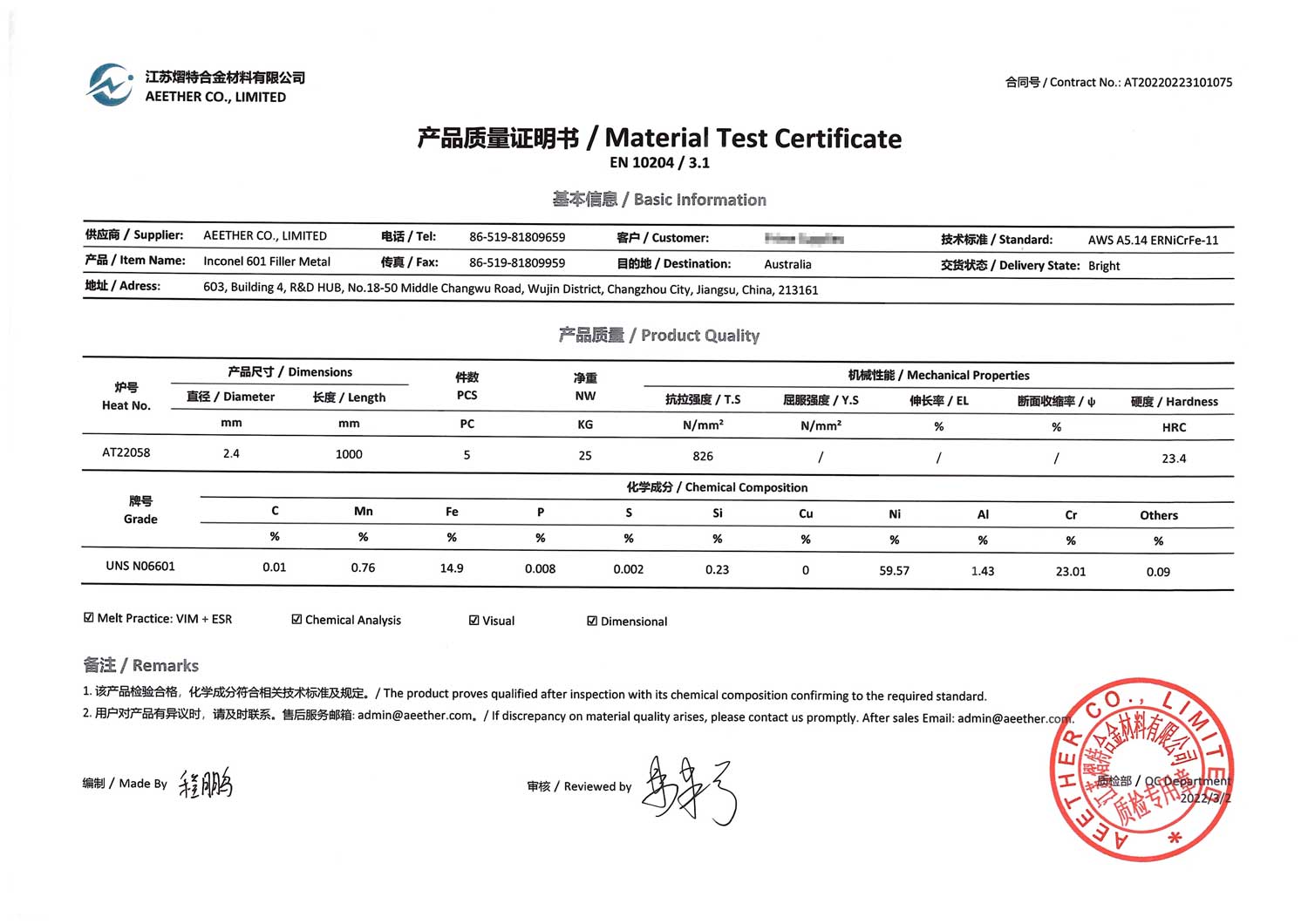

Provide Material Inspection Certificate before Shipment

The material test certificate is a factory's guarantee of the quality of their products. Therefore, if your supplier is willing to provide a material test certificate that meets the requirements before shipment, it means that they have full confidence in the quality of the goods.

A standard material test certificate should have the following information:

- ☑ Supplier Information

- ☑ Customer Information

- ☑ Destination

- ☑ Standard

- ☑ Delivery State

- ☑ Heat Number

- ☑ Dimensions, Pieces & Net Weight

- ☑ Mechanical Properties

- ☑ Grade & Chemical Composition

- ☑ Supplier's Quality Stamp

- ☑ Other Information

Provide PMI Test Photos and Size Photos before Shipment

PMI testing can clearly measure the chemical composition of materials. If the supplier can provide photos of the PMI test and the corresponding size measurement photos before shipment, it means that the chemical properties and size of the material can meet the requirements. You can receive your order with confidence.

It should be noted that some handheld spectrometers have a certain tolerance in the measurement results, so some elements may be detected out of range. But if the grade shown on the equipment is the same as your requirement, then there is basically no problem with the material.

Provide Samples for Testing before Shipment

We have some customers inquiring whether we can provide samples before placing the order.

Unfortunately, nickel alloys come in a wide range of grades, product forms, and sizes. It is difficult to provide samples that just meet the requirements.

This is totally possible if you ask for samples before shipping. Suppliers who are confident in product quality will be willing to provide samples to customers for testing after production is completed to eliminate customer doubts.

Provide the Test Report Issued by the Testing Institutions before Shipment

Some products have performance requirements in addition to chemical composition. In this case, the PMI test alone is not enough. We recommend that you ask the supplier to send the material to a professional testing institutions for testing and submit the corresponding testing report.

Recommended testing institutions:

Testing Report:

Third-party Inspection before Shipment

Some single pieces of goods are relatively large in size and weight, and are not suitable for being sent to testing institutions for testing. In this case, we recommend third-party testing. The inspectors will directly enter the factory for inspection and provide corresponding inspection reports.

Recommended third-party testing institutions:

Contact

We are a professional nickel alloy supplier. We support all the above inspection methods. If you have a need to purchase nickel alloys, please do not hesitate to contact us.